It typically connects to a flywheel, to reduce the pulsation characteristic of the four-stroke cycle, and sometimes a torsional or vibrational damper at the opposite end, to reduce the torsion vibrations often caused along the length of the crankshaft by the cylinders farthest from the output end acting on the torsional elasticity of the metal.

History

Classical Antiquity

The earliest evidence for the crank as part of a machine, that is in combination with a connecting rod, anywhere in the world appears in the late Roman Hierapolis sawmill from the 3rd century AD and two Roman stone sawmills at Gerasa, Roman Syria, and Ephesus, Asia Minor (both 6th century AD). On the pediment of the Hierapolis mill, a waterwheel fed by a mill race is shown powering via a gear train two frame saws which cut rectangular blocks by the way of some kind of connecting rods and, through mechanical necessity, cranks. The accompanying inscription is inGreek.

The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train. In ancient literature, we find a reference to the workings of water-powered marble saws close to Trier, now Germany, by the late 4th century poet Ausonius;about the same time, these mill types seem also to be indicated by the Christian saint Gregory of Nyssa from Anatolia, demonstrating a diversified use of water-power in many parts of the Roman Empire. The three finds push back the date of the invention of the crank and connecting rod back by a full millennium; for the first time, all essential components of the much later steam engine were assembled by one technological culture:

With the crank and connecting rod system, all elements for constructing a steam engine (invented in 1712) — Hero's aeolipile(generating steam power), the cylinder and piston (in metal force pumps), non-return valves (in water pumps), gearing (in water mills and clocks) — were known in Roman times.

The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train. In ancient literature, we find a reference to the workings of water-powered marble saws close to Trier, now Germany, by the late 4th century poet Ausonius;about the same time, these mill types seem also to be indicated by the Christian saint Gregory of Nyssa from Anatolia, demonstrating a diversified use of water-power in many parts of the Roman Empire. The three finds push back the date of the invention of the crank and connecting rod back by a full millennium; for the first time, all essential components of the much later steam engine were assembled by one technological culture:

With the crank and connecting rod system, all elements for constructing a steam engine (invented in 1712) — Hero's aeolipile(generating steam power), the cylinder and piston (in metal force pumps), non-return valves (in water pumps), gearing (in water mills and clocks) — were known in Roman times.

Middle Ages

In the 9th century, the non-manual crank appears in several of the hydraulic machines described by theBanu Musa brothers in their Book of Ingenious Devices.Two of them contain an action which approximates to that of a crankshaft and only a small modification would have required to convert it to a crankshaft.

In reality, however, these devices made only partial rotations and could only be lightly loaded, while the historian of technology Lynn White did not classify them even as the simplest application of a crank.

The first known use of a crankshaft in a chain pump was in one of Al-Jazari's (1136–1206) saqiyamachines.The concept of minimizing intermittent working is also first implied in one of al-Jazari's saqiyachain pumps, which was for the purpose of maximising the efficiency of the saqiya chain pump Al-Jazari also constructed a water-raising saqiya chain pump which was run by hydropower rather thanmanual labour, though the Chinese were also using hydropower for chain pumps prior to him. Saqiya machines like the ones he described have been supplying water in Damascus since the 13th century up until modern times, and were in everyday use throughout the medieval Islamic world. Al-Jazaridescribed a crank and connecting rod system in a rotating machine in two of his water-raising machines. His twin-cylinder pumpincorporated a crankshaft, but the device was unnecessarily complex indicating that he still did not fully understand the concept of power conversion. Citing the Byzantine siphon used for discharging Greek fire as an inspiration, Al-Jazari went on to describe the first suctionpipes, suction pump, double-action pump, and made early uses of valves and a crankshaft-connecting rod mechanism, when he invented atwin-cylinder reciprocating piston suction pump. This pump is driven by a water wheel, which drives, through a system of gears, an oscillating slot-rod to which the rods of two pistons are attached. The pistons work in horizontally opposed cylinders, each provided with valve-operated suction and delivery pipes. The delivery pipes are joined above the centre of the machine to form a single outlet into the irrigation system. This water-raising machine had a direct significance for the development of modern engineering. This pump is remarkable for three reasons:

The first known use of a true suction pipe (which sucks fluids into a partial vacuum) in a pump.

The first application of the double-acting principle.

The conversion of rotary to reciprocating motion, via the crank-connecting rod mechanism.

Al-Jazari's suction piston pump could lift 13.6 m (45 ft) of water, with the help of delivery pipes. This was more advanced than the suction pumps that appeared in 15th-century Europe, which lacked delivery pipes. It was not, however, any more efficient than a noria commonly used by the Muslim world at the time.

Taqi al-Din incorporated a crankshaft in a six-cylinder pump in 1551.The Italian physician Guido da Vigevano

(c. 1280−1349), planning for a new crusade, made illustrations for a paddle boat and war carriages that were propelled by manually turned compound cranks and gear wheels (center of image).The Luttrell Psalter, dating to around 1340, describes a grindstone which was rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century;

In China, the potential of the crank of converting circular motion into reciprocal one never seems to have been fully realized, and the crank was typically absent from such machines until the turn of the 20th century.

In reality, however, these devices made only partial rotations and could only be lightly loaded, while the historian of technology Lynn White did not classify them even as the simplest application of a crank.

The first known use of a crankshaft in a chain pump was in one of Al-Jazari's (1136–1206) saqiyamachines.The concept of minimizing intermittent working is also first implied in one of al-Jazari's saqiyachain pumps, which was for the purpose of maximising the efficiency of the saqiya chain pump Al-Jazari also constructed a water-raising saqiya chain pump which was run by hydropower rather thanmanual labour, though the Chinese were also using hydropower for chain pumps prior to him. Saqiya machines like the ones he described have been supplying water in Damascus since the 13th century up until modern times, and were in everyday use throughout the medieval Islamic world. Al-Jazaridescribed a crank and connecting rod system in a rotating machine in two of his water-raising machines. His twin-cylinder pumpincorporated a crankshaft, but the device was unnecessarily complex indicating that he still did not fully understand the concept of power conversion. Citing the Byzantine siphon used for discharging Greek fire as an inspiration, Al-Jazari went on to describe the first suctionpipes, suction pump, double-action pump, and made early uses of valves and a crankshaft-connecting rod mechanism, when he invented atwin-cylinder reciprocating piston suction pump. This pump is driven by a water wheel, which drives, through a system of gears, an oscillating slot-rod to which the rods of two pistons are attached. The pistons work in horizontally opposed cylinders, each provided with valve-operated suction and delivery pipes. The delivery pipes are joined above the centre of the machine to form a single outlet into the irrigation system. This water-raising machine had a direct significance for the development of modern engineering. This pump is remarkable for three reasons:

The first known use of a true suction pipe (which sucks fluids into a partial vacuum) in a pump.

The first application of the double-acting principle.

The conversion of rotary to reciprocating motion, via the crank-connecting rod mechanism.

Al-Jazari's suction piston pump could lift 13.6 m (45 ft) of water, with the help of delivery pipes. This was more advanced than the suction pumps that appeared in 15th-century Europe, which lacked delivery pipes. It was not, however, any more efficient than a noria commonly used by the Muslim world at the time.

Taqi al-Din incorporated a crankshaft in a six-cylinder pump in 1551.The Italian physician Guido da Vigevano

(c. 1280−1349), planning for a new crusade, made illustrations for a paddle boat and war carriages that were propelled by manually turned compound cranks and gear wheels (center of image).The Luttrell Psalter, dating to around 1340, describes a grindstone which was rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century;

In China, the potential of the crank of converting circular motion into reciprocal one never seems to have been fully realized, and the crank was typically absent from such machines until the turn of the 20th century.

Renaissance

The first depictions of the compound crank in the carpenter's appear between 1420 and 1430 in various northern European artwork. The rapid adoption of the compound crank can be traced in the works of the Anonymous of the Hussite Wars, an unknown German engineer writing on the state of the military technology of his day: first, the connecting-rod, applied to cranks, reappeared, second, double compound cranks also began to be equipped with connecting-rods and third, the flywheel was employed for these cranks to get them over the 'dead-spot'.

In Renaissance Italy, the earliest evidence of a compound crank and connecting-rod is found in the sketch books of Taccola, but the device is still mechanically misunderstood. A sound grasp of the crank motion involved demonstrates a little later Pisanello who painted a piston-pump driven by a water-wheel and operated by two simple cranks and two connecting-rods.

One of the drawings of the Anonymous of the Hussite Wars shows a boat with a pair of paddle-wheels at each end turned by men operating compound cranks (see above). The concept was much improved by the Italian Roberto Valturio in 1463, who devised a boat with five sets, where the parallel cranks are all joined to a single power source by one connecting-rod, an idea also taken up by his compatriot Francesco di Giorgio.

Crankshafts were also described by Konrad Kyeser (d. 1405), Leonardo da Vinci (1452–1519) and a Dutch "farmer" by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's The Diverse and Artifactitious Machines of 1588 alone depicts eighteen examples, a number which rises in the Theatrum Machinarum Novum by Georg Andreas Böckler to 45 different machines, one third of the total.

Crankshafts were also described by Konrad Kyeser (d. 1405), Leonardo da Vinci (1452–1519) and a Dutch "farmer" by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's The Diverse and Artifactitious Machines of 1588 alone depicts eighteen examples, a number which rises in the Theatrum Machinarum Novum by Georg Andreas Böckler to 45 different machines, one third of the total.

Design

Large engines are usually multicylinder to reduce pulsations from individual firing strokes, with more than one piston attached to a complex crankshaft. Many small engines, such as those found in mopeds or garden machinery, are single cylinder and use only a single piston, simplifying crankshaft design. This engine can also be built with no riveted seam.

Bearings

The crankshaft has a linear axis about which it rotates, typically with several bearing journals riding on replaceable bearings (the main bearings) held in the engine block. As the crankshaft undergoes a great deal of sideways load from each cylinder in a multicylinder engine, it must be supported by several such bearings, not just one at each end. This was a factor in the rise of V8 engines, with their shorter crankshafts, in preference to straight-8 engines. The long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher compression ratios and higher rotational speeds. High performance engines often have more main bearings than their lower performance cousins for this reason.

Piston stroke

The distance the axis of the crank throws from the axis of the crankshaft determines the piston stroke measurement, and thus engine displacement. A common way to increase the low-speed torque of an engine is to increase the stroke. This also increases the reciprocating vibration, however, limiting the high speed capability of the engine. In compensation, it improves the low speed operation of the engine, as the longer intake stroke through smaller valve(s) results in greater turbulence and mixing of the intake charge. For this reason, even such high speed production engines as current Honda engines are classified as "under square" or long-stroke, in that the stroke is longer than the diameter of the cylinder bore.

Engine configuration

The configuration and number of pistons in relation to each other and the crank leads to straight, V or flat engines. The same basic engine block can be used with different crankshafts, however, to alter the firing order; for instance, the 90° V6 engine configuration, in older days sometimes derived by using six cylinders of a V8 engine with what is basically a shortened version of the V8 crankshaft, produces an engine with an inherent pulsation in the power flow due to the "missing" two cylinders. The same engine, however, can be made to provide evenly spaced power pulses by using a crankshaft with an individual crank throw for each cylinder, spaced so that the pistons are actually phased 120° apart, as in the GM 3800 engine. While production V8 engines use four crank throws spaced 90° apart, high-performance V8 engines often use a "flat" crankshaft with throws spaced 180° apart. The difference can be heard as the flat-plane crankshafts result in the engine having a smoother, higher-pitched sound than cross-plane (for example, IRL IndyCar Series compared to NASCAR Nextel Cup, or a Ferrari 355 compared to a Chevrolet Corvette). See the main article on crossplane crankshafts.

Engine balance

For some engines it is necessary to provide counterweights for the reciprocating mass of each piston and connecting rod to improve engine balance. These are typically cast as part of the crankshaft but, occasionally, are bolt-on pieces. While counter weights add a considerable amount of weight to the crankshaft, it provides a smoother running engine and allows higher RPMs to be reached.Rotary engines

Many early aircraft engines (and a few in other applications) had the crankshaft fixed to the airframe and instead the cylinders rotated, known as a rotary engine design. Rotary engines such as the Wankel engine are referred to as pistonless rotary engines.In the Wankel engine, also called a rotary engine, the rotors drive the eccentric shaft, which could be considered the equivalent of the crankshaft in a piston engine.

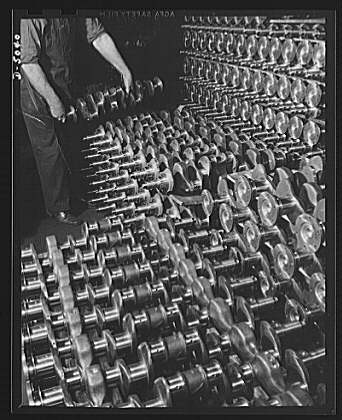

Construction

Forging and casting

Crankshafts can be monolithic (made in a single piece) or assembled from several pieces. Monolithic crankshafts are most common, but some smaller and larger engines use assembled crankshafts.

Crankshafts can be forged from a steel bar usually through roll forging or cast in ductile steel. Today more and more manufacturers tend to favor the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent dampening. With forged crankshafts, vanadium microalloyed steels are mostly used as these steels can be air cooled after reaching high strengths without additional heat treatment, with exception to the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high alloy steels. Carbon steels are also used, but these require additional heat treatment to reach the desired properties. Iron crankshafts are today mostly found in cheaper production engines (such as those found in the Ford Focus diesel engines) where the loads are lower. Some engines also use cast iron crankshafts for low output versions while the more expensive high output version use forged steel.

Crankshafts can be forged from a steel bar usually through roll forging or cast in ductile steel. Today more and more manufacturers tend to favor the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent dampening. With forged crankshafts, vanadium microalloyed steels are mostly used as these steels can be air cooled after reaching high strengths without additional heat treatment, with exception to the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high alloy steels. Carbon steels are also used, but these require additional heat treatment to reach the desired properties. Iron crankshafts are today mostly found in cheaper production engines (such as those found in the Ford Focus diesel engines) where the loads are lower. Some engines also use cast iron crankshafts for low output versions while the more expensive high output version use forged steel.

Machining

Crankshafts can also be machined out of a billet, often using a bar of high quality vacuum remelted steel. Even though the fiber flow (local inhomogeneities of the material's chemical composition generated during casting) doesn’t follow the shape of the crankshaft (which is undesirable), this is usually not a problem since higher quality steels which normally are difficult to forge can be used. These crankshafts tend to be very expensive due to the large amount of material removal which needs to be done by using lathes and milling machines, the high material cost and the additional heat treatment required. However, since no expensive tooling is required, this production method allows small production runs of crankshafts to be made without high costs.Fatigue strength

The fatigue strength of crankshafts is usually increased by using a radius at the ends of each main and crankpin bearing. The radius itself reduces the stress in these critical areas, but since the radii in most cases are rolled, this also leaves some compressive residual stress in the surface which prevents cracks from forming.

Hardening

Most production crankshafts use induction hardened bearing surfaces since that method gives good results with low costs. It also allows the crankshaft to be reground without having to redo the hardening. But high performance crankshafts, billet crankshafts in particular, tend to usenitridization instead. Nitridization is slower and thereby more costly, and in addition it puts certain demands on the alloying metals in the steel, in order to be able to create stable nitrides. The advantage with nitridization is that it can be done at low temperatures, it produces a very hard surface and the process will leave some compressive residual stress in the surface which is good for the fatigue properties of the crankshaft. The low temperature during treatment is advantageous in that it doesn’t have any negative effects on the steel, such as annealing. With crankshafts that operate on roller bearings, the use of carburization tends to be favored due to the high Hertzian contact stresses in such an application. Like nitriding, carburization also leaves some compressive residual stresses in the surface.

Counterweights

Some expensive, high performance crankshafts also use heavy-metal counterweights to make the crankshaft more compact. The heavy-metal used is most often a tungsten alloy but depleted uranium has also been used. A cheaper option is to use lead, but compared with tungsten its density is much lower.

Stress on crankshafts

The shaft is subjected to various forces but generally needs to be analysed in two positions. Firstly, failure may occur at the position of maximum bending; this may be at the centre of the crank or at either end. In such a condition the failure is due to bending and the pressure in the cylinder is maximal. Second, the crank may fail due to twisting, so the conrod needs to be checked for shear at the position of maximal twisting. The pressure at this position is the maximal pressure, but only a fraction of maximal pressure.Crank Sensor

A crank sensor is a component used in an internal combustion engine to monitor the position or rotational speed of the crankshaft. This information is used by engine management systems to control ignition system timing and other engine parameters. Before electronic crank sensors were available, the distributor would have to be manually adjusted to a timing mark on the engine.

The crank sensor can be used in combination with a similar camshaft position sensor to monitor the relationship between the pistons andvalves in the engine, which is particularly important in engines with variable valve timing. It is also commonly the primary source for the measurement of engine speed in revolutions per minute.

Crank sensors in engines usually consist of magnets and an inductive coil, or they may be based on magnetically triggered Hall effectsemiconductor devices. Common mounting locations include the main crank pulley, the flywheel, and occasionally on the crankshaft itself. This sensor is the most important sensor in modern day engines. When it fails, there is a small chance the engine will start (engine will likely cut out after a few minutes of driving) but it mostly will not start.

Some engines, such as GM's Premium V family, use crank position sensors which read a reluctor ring integral to the harmonic balancer. This is a much more accurate method of determining the position of the crankshaft, and allows the computer to determine within a few degrees the exact position of the crankshaft (and thereby all connected components) at any given time.

Another type of crank sensor is used on bicycles to monitor the position of the crankset, usually for the cadence readout of a cyclocomputer.

The crank sensor can be used in combination with a similar camshaft position sensor to monitor the relationship between the pistons andvalves in the engine, which is particularly important in engines with variable valve timing. It is also commonly the primary source for the measurement of engine speed in revolutions per minute.

Crank sensors in engines usually consist of magnets and an inductive coil, or they may be based on magnetically triggered Hall effectsemiconductor devices. Common mounting locations include the main crank pulley, the flywheel, and occasionally on the crankshaft itself. This sensor is the most important sensor in modern day engines. When it fails, there is a small chance the engine will start (engine will likely cut out after a few minutes of driving) but it mostly will not start.

Some engines, such as GM's Premium V family, use crank position sensors which read a reluctor ring integral to the harmonic balancer. This is a much more accurate method of determining the position of the crankshaft, and allows the computer to determine within a few degrees the exact position of the crankshaft (and thereby all connected components) at any given time.

Another type of crank sensor is used on bicycles to monitor the position of the crankset, usually for the cadence readout of a cyclocomputer.

No comments:

Post a Comment